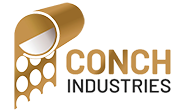

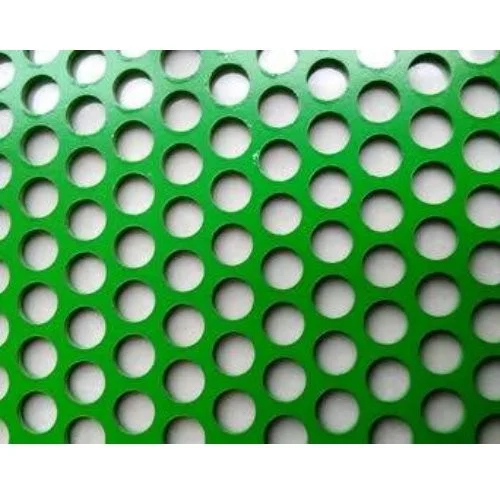

MS Perforated Sheet

Product Details:

- Usage Industrial

- Surface Treatment Polishing

- Size Standard

- Material Mild steel

- Type Sheet

- Technique Hot Rolled

- Feature Rust proof

- Click to View more

MS Perforated Sheet Price And Quantity

- 5 Number

- 1230 INR/Square Foot

MS Perforated Sheet Product Specifications

- Hot Rolled

- Rust proof

- Standard

- Polishing

- Mild steel

- Industrial

- Sheet

MS Perforated Sheet Trade Information

- 5000 Number Per Month

- Days

- All India

Product Description

Today

crca perforated sheet short specification please

Here™s a brief specification for CRCA perforated sheets:

-

Material: Cold Rolled Closed Annealed (CRCA) steel

-

Thickness: Typically ranges from 0.35 mm to 3.2 mm

-

Width: Up to 1870 mm

-

Hole Diameters: 0.4 mm to 2 mm

-

Surface Finish: Available in Dull, Bright, and Matt

-

Edge Type: Mill Edge / Slit Edge

-

Applications: Used in manufacturing, filtration, decoration, and machinery components

Would you like more details on a specific aspect?

total product details please

Here are the full details for CRCA perforated sheets:

Material & Grades

-

Material: Cold Rolled Closed Annealed (CRCA) steel

-

Grades: CQ, DQ, DDQ, EDDQ, IF, HIF, HSS, Bake Hardening, High Strength Micro Alloyed, Dual Phase Steel

Dimensions

-

Thickness: 0.35 mm to 3.2 mm

-

Width: Up to 1870 mm

-

Hole Diameters: 0.4 mm to 2 mm

-

Sheet Size: Standard sizes available, custom sizes on request

Surface Finish & Edge Type

-

Surface Finish: Dull, Bright, Matt

-

Edge Type: Mill Edge / Slit Edge

Mechanical Properties

-

Yield Strength: 120 N/mm² to 350 N/mm²

-

Tensile Strength: 270 N/mm² to 410 N/mm²

-

Elongation: 28% to 40% (depending on grade)

Applications

-

Industrial Use: Machinery components, filtration, automotive, furniture, appliances

-

Decorative Use: Architectural designs, interior panels

-

Manufacturing: Precision engineering, perforated coils

Would you like details on pricing or suppliers? ðŸŠ

gi perforated sheet short details

Here™s a brief specification for GI perforated sheets:

-

Material: Galvanized Iron (GI)

-

Thickness: 0.2 mm to 25 mm

-

Width: 600 mm to 2000 mm

-

Hole Diameters: 0.5 mm to 100 mm

-

Surface Finish: Zinc-coated for corrosion resistance

-

Edge Type: Mill Edge / Slit Edge

-

Applications: Used in filtration, sound insulation, anti-slip surfaces, and industrial protection

Would you like more details on a specific aspect? ðŸŠ

product description

Here™s a detailed product description for GI perforated sheets:

Overview

Galvanized Iron (GI) perforated sheets are metal sheets that have been punched or stamped with holes in various patterns. They are coated with zinc to enhance corrosion resistance, making them ideal for industrial, architectural, and decorative applications.

Specifications

-

Material: Galvanized Iron (GI)

-

Thickness: 0.2 mm to 25 mm

-

Width: 600 mm to 2000 mm

-

Hole Diameter: 0.5 mm to 100 mm

-

Hole Shapes: Round, square, hexagonal, slotted, and custom patterns

-

Surface Finish: Zinc-coated for rust protection

-

Edge Type: Mill Edge / Slit Edge

Key Features

-

Corrosion Resistance: Zinc coating prevents rust and extends durability

-

High Strength: Suitable for heavy-duty applications

-

Ventilation & Drainage: Allows air, light, and liquids to pass through

-

Aesthetic Appeal: Used in decorative panels and architectural designs

-

Customizable: Available in different hole sizes and patterns

Applications

-

Industrial Use: Machinery covers, filtration systems, ventilation panels

-

Architectural Use: Ceiling panels, facades, partitions

-

Safety & Protection: Anti-slip flooring, fencing, security screens

-

Automotive & Transportation: Soundproofing panels, vehicle grilles

Would you like details on pricing or suppliers? ðŸŠ

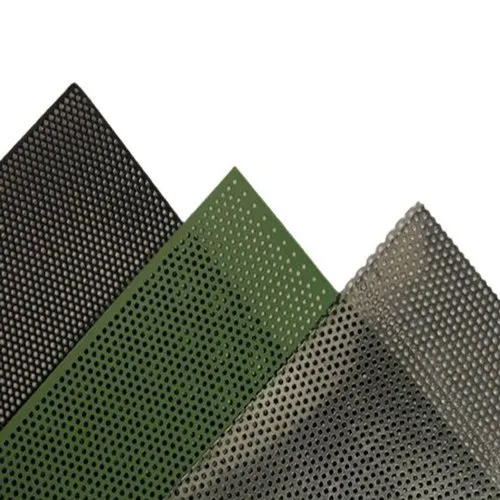

m s perforated short specification

Here™s a brief specification for MS (Mild Steel) perforated sheets:

-

Material: Mild Steel (MS)

-

Thickness: 0.2 mm to 25 mm

-

Width: 600 mm to 3500 mm

-

Hole Shapes: Round, square, diamond, and custom patterns

-

Surface Finish: Available with galvanizing, painting, or powder coating

-

Edge Type: Mill Edge / Slit Edge

-

Applications: Used in construction, machinery, filtration, noise reduction, and decoration

Would you like more details on a specific aspect? ðŸŠ

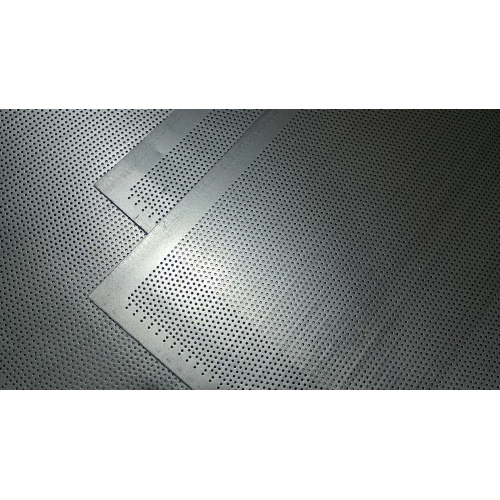

production specification

Here™s the production specification for MS (Mild Steel) perforated sheets:

Material & Grades

-

Material: Mild Steel (MS)

-

Grades: Available in low-carbon steel, high-carbon steel, and alloy steel

Dimensions

-

Thickness: 0.2 mm to 25 mm

-

Width: 600 mm to 3500 mm

-

Hole Shapes: Round, square, diamond, hexagonal, and custom patterns

-

Sheet Size: Standard sizes available, custom sizes on request

Manufacturing Process

-

Raw Material Selection: High-quality MS sheets are chosen based on required specifications.

-

Perforation: CNC punching or laser cutting is used to create precise hole patterns.

-

Surface Treatment: Sheets undergo galvanizing, painting, or powder coating for durability.

-

Quality Inspection: Sheets are tested for dimensional accuracy, strength, and corrosion resistance.

-

Packaging & Dispatch: Sheets are packed securely for transportation.

Mechanical Properties

-

Yield Strength: 250 N/mm² to 400 N/mm²

-

Tensile Strength: 350 N/mm² to 550 N/mm²

-

Elongation: 20% to 35% (depending on grade)

Applications

-

Industrial Use: Machinery covers, filtration systems, ventilation panels

-

Construction: Fencing, partitions, noise reduction panels

-

Automotive & Transportation: Soundproofing panels, vehicle grilles

-

Decorative & Architectural: Ceiling panels, facades, furniture designs

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese